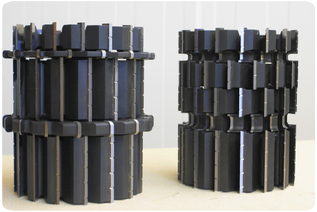

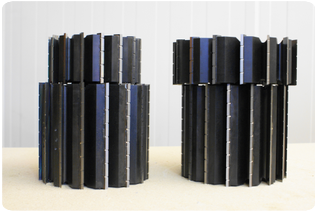

W 2020 Spring-groove cutter

Problem:

Every extruded material has a layer on top of its surface(so- called skins) which show differences in height and thickness depending on the extruder type. This can cause problems during the milling process like the following:

fast tool wear in the area of the skins

cracked edges or frazzling at the cover layers

Solution:

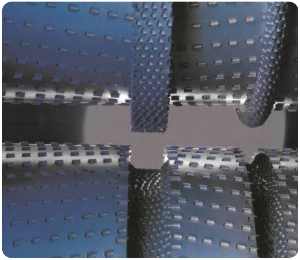

Through the skew of the knife-like toothing (instead of the conventional rasp cut) a cracked edge will always be pulled into the disc area to be milled. Moreover the knife-like blades provide a complete overlap of each blade to one another which leads to a longer stability time.

Advantages compared to carbide-tipped tools:

runs rather quietly

good price- / performance ratio

short production time even for the most complicated forms