balancing

The spindle speed of modern machine tools has increased continuously in the last couple of years in order to achieve a greater cutting performance and to work more economically and profitably. This increase has raised the requirements of the tools and version holders that are used since higher spindle speed has a more noticeable impact imbalance. Consequences are vibrations, bad quality of the surface and shorter stability time.

The high-precision balancing of the tools and the holders allows the machine tool to reach its full capacity with regards to speed, cutting performance and surface quality. This is because balancing itself causes lower vibration levels. That, in turn, reduces wear and tear of the spindle, the tool, which then not only reduces downtime but also increases process reliability and stability.

As a matter of principle all of our tools and holders are balanced.

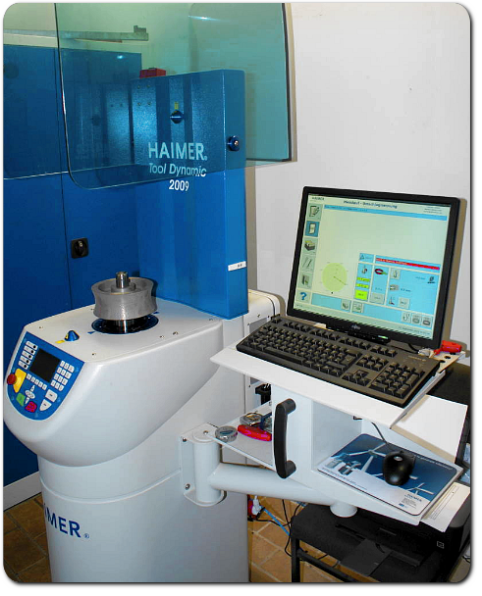

The IWD company provides the following services:

Dynamically balancing on two levels (max. length of the rotor 600mm)

Statically balancing up until a diameter of 380mm and a length of 600mm

Balancing up until 35kg max.

Balancing up until the speed of 60000 1/min.